___________

___________

___________

___________

|

Depending on the signal and location, there are several ways I can fit a servo

The simplest method is to just glue the motor to the signal base, this can be either horizontally or vertically (if only max of 2).

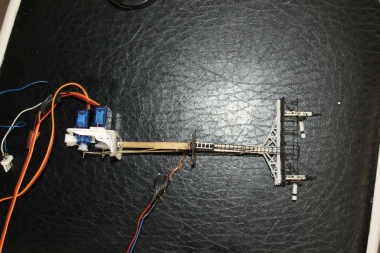

The use of a servo mount opens up the possibility to reduce the baseboard surface area required.

In the photograph the signal is attached to the servo mount by means of telescopic brass tubing. An added refinement would be to attach a couple of blocks to space it away from the under-

The signal would be held securely, but upon removal of the pin, it could be removed for such as maintenance and transport

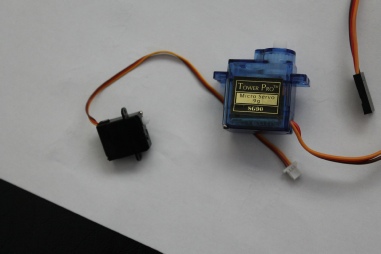

The use of low voltage servos presents a slight problem in that the voltage from a servo control board would normally run the risk of burning out the motor.

A couple of resistors can reduce the voltage to a safe level.

I use smd resistors as outlined in my thread on RMWeb to effect this reduction to approx 3.5vdc. You also need to change the plugs.

A servo mount fixed directly to the signal allows for the easy replacement of any faulty servos